7 Ways to Stop or Slow Metal Corrosion

Every year, about US$2.5 trillion is lost to corrosion globally. That’s more than 3 percent of the global GDP. But the concern over metal corrosion is not solely a financial issue. It’s one of safety and health...Thursday, January 30th 2020, 1:43 am

Every year, about US$2.5 trillion is lost to corrosion globally. That’s more than 3 percent of the global GDP.

But the concern over metal corrosion is not solely a financial issue. It’s one of safety and health as well.

Corroded metal can affect not only the structure that contains the metal but people using or within the vicinity of the metal. Cases of corroded buildings and bridges collapsing, pipes leaking, and medical implants poisoning people’s blood aren’t new.

Ultimately, there’s absolutely nothing good that can come from the corrosion of metals. It’s the reason you should try to prevent it or at least slow it down.

Keep on reading to learn more.

The Definition of Metal Corrosion

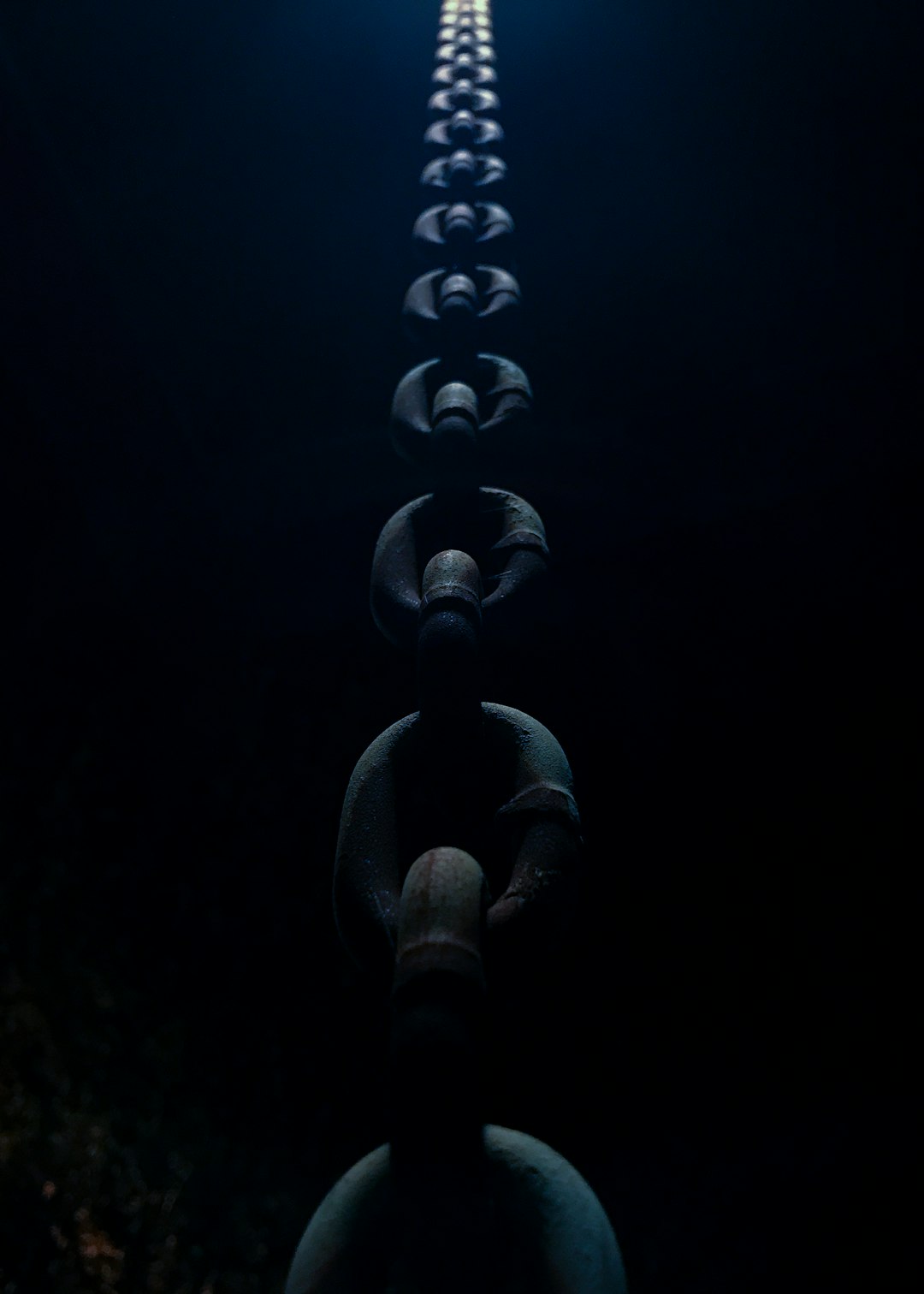

Corrosion refers to the process of metal deterioration due to chemical reactions between the metal and the surrounding environment. The rate of this deterioration depends on the type of metal as well as the environmental conditions, especially the gases that come to contact with the metal.

Which Metals Corrode?

Corrosion can happen to any metal. Some metals, such as pure iron, tend to corrode a lot more quickly than others. The combination of iron and other alloys to make stainless steel significantly slows down the process of corrosion.

There’s a small group of metals that are a lot less reactive compared to other metals. These are referred to as Noble Metals and include gold, silver, platinum, rhodium, and palladium. Noble metals rarely corrode.

How to Avert Corrosion in Metals

While corrosion is so prevalent and destructive, it can be controlled through simple prevention techniques. Here are seven proven ways to keep corrosion at bay.

1. Choose Corrosion-Resistant Metal

When it comes to metal corrosion, prevention is the best cure. There’s hardly an easier way to stop corrosion than by using metals that are not prone to corrosion in your projects. Aluminum and stainless steel are good examples.

When buying metallic products, buy those made from metals that do not corrode easily. The idea is to reduce the need for added corrosion protection.

2. Use Protective Coatings

Applying a coat of paint, such as rubber paint, is one of the most cost-effective methods of preventing corrosion. The paint acts as a barrier, preventing corrosion-causing electrochemical charges from transferring to the metal underneath the coating.

You could also apply a powder coating to the metal surface and heat it to form a smooth protective film on the metal. The most popular powder compositions include epoxy, acrylic, nylon, polyester, and urethane.

3. Take Appropriate Environmental Measures

As we mentioned earlier, corrosion happens when there’s a chemical reaction between a metal and the gases in the environment around it. It thus follows that if you can control the environment, you can reduce unwanted reactions that cause corrosion.

Simple ways to control the environment include reducing exposure to moisture or seawater. More complex measures include controlling the levels of oxygen, chlorine, or sulfur in the environment around the metal.

4. Use Sacrificial Coatings

In sacrificial coating, an additional coat of a metal that’s likely to oxidize is added on the surface of the metal you want to protect from corrosion. Sacrificial coating can be achieved through two methods:

- Cathodic Protection – this method involves coating iron alloy steel with zinc. The process is known as galvanizing. As zinc is more active than steel, it oxides quickly and prevents the steel from corroding.

- Anodic Protection – this technique involves applying a coat of a less active metal on steel. Usually, tin is used as it does not corrode easily. Therefore, as long as the coat is in place, the steel will always be protected.

5. Try Metal Plating

Plating is almost similar to coating in that a thin layer of metal is applied to the metal you intend to protect. Besides inhibiting corrosion, the metal layer provides aesthetic finishes. Generally, there are four types of metallic plating:

- Electroplating: this technique involves depositing a thin layer of metal such as chromium or nickel on the substrate metal in an electrolyte bath.

- Mechanical Plating: mechanical plating involves cold welding metal powder to the substrate metal. The substrate plus the powder and some glass beads are tumbled in an aqueous solution. Typically, metal plating involves applying cadmium or zinc to tiny metal parts.

- Electroless: in this method, a coating metal like nickel or cobalt is deposited on a substrate metal through a chemical reaction. This plating technique is non-electric.

- Hot Dipping: this is a simple coating technique that involves immersing the substrate in a molten bath of the protective metal. The protective metal then forms a thin layer on the substrate metal.

6. Consider Corrosion Inhibitors

Corrosion inhibitors prevent corrosion by reacting with the surface of the metal and surrounding gases to subdue electrochemical reactions that may cause corrosion. These chemicals form a protective film on the surface of the metal.

You can apply corrosion inhibitors in the form of a protective coating through dispersion techniques. You can also apply these chemicals as a solution. The process of applying corrosion inhibitors is typically known as passivation.

The commonest applications of corrosion inhibitors are in water treatment, petroleum refining, and chemical treatment industries.

7. Try Design Modification

Modifying the design of metal can go a long way in reducing corrosion. The approach can also enhance the durability of the existing anti-corrosive coating on the metal.

So how do you go about it? Well, you could try to improve the design, so the metal does not trap water and dust or encourage the free movement of air. Pay attention to regular maintenance as well.

Preventing Metal Corrosion Is Easy

Metal corrosion will always be a fact of life for every person who uses metal. Knowing what causes corrosion and what you can do to stop it, however, can help you run preventive measures on it before it becomes a menace.

Keep in mind that exposed surfaces are the most vulnerable, so do your best to treat them if you can. Controlling the environment by eliminating moisture can also help slow corrosion to a manageable pace.

To read more great content like this, please keep visiting our website.

Information contained on this page is provided by an independent third-party content provider. Frankly and this Site make no warranties or representations in connection therewith. If you are affiliated with this page and would like it removed please contact pressreleases@franklymedia.com

More Like This

January 30th, 2020

December 12th, 2024

December 12th, 2024

December 11th, 2024

Top Headlines

December 12th, 2024

December 11th, 2024

December 11th, 2024

December 11th, 2024